homemade injection molding machine part 2

Mold a single tensile bar - 50 ton machine Mold a front end of a car - 5000 ton machine Typical sizes are 100-1000 tons For complicated parts A. The quick-change tools will be molding a pair of tongs and a bowl respectively.

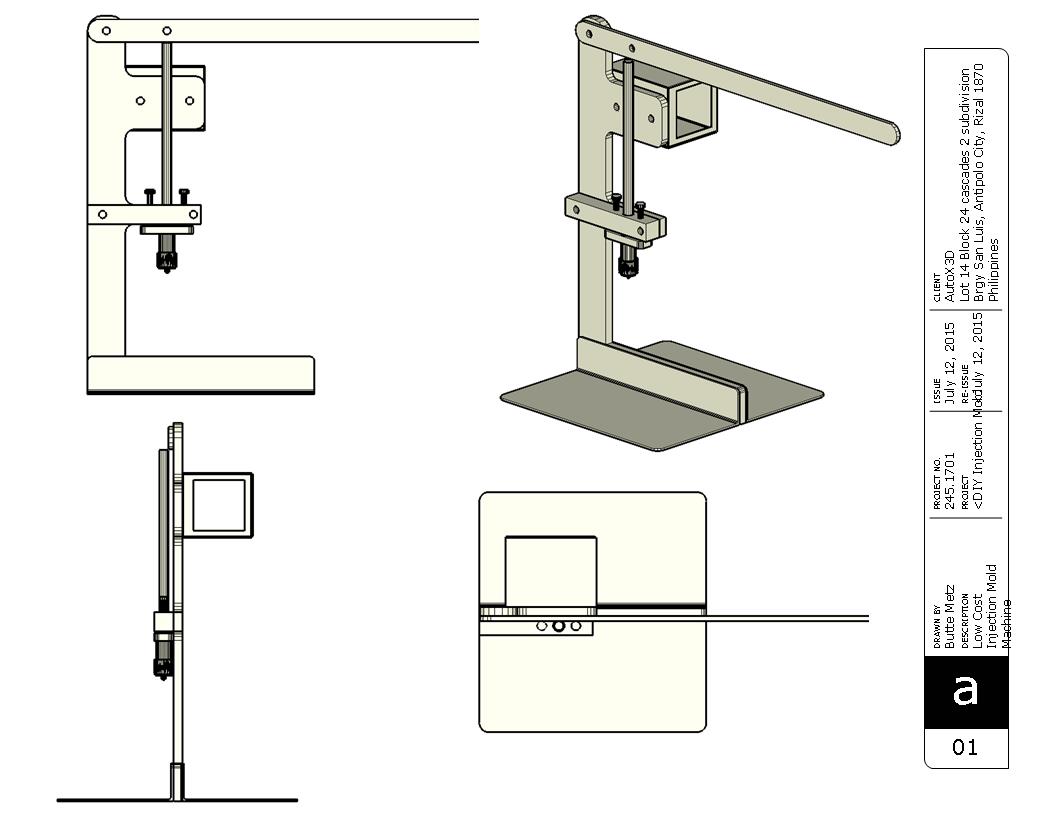

Diy Plastic Injection Molder Openbuilds

The melt must be homogeneous and not degraded.

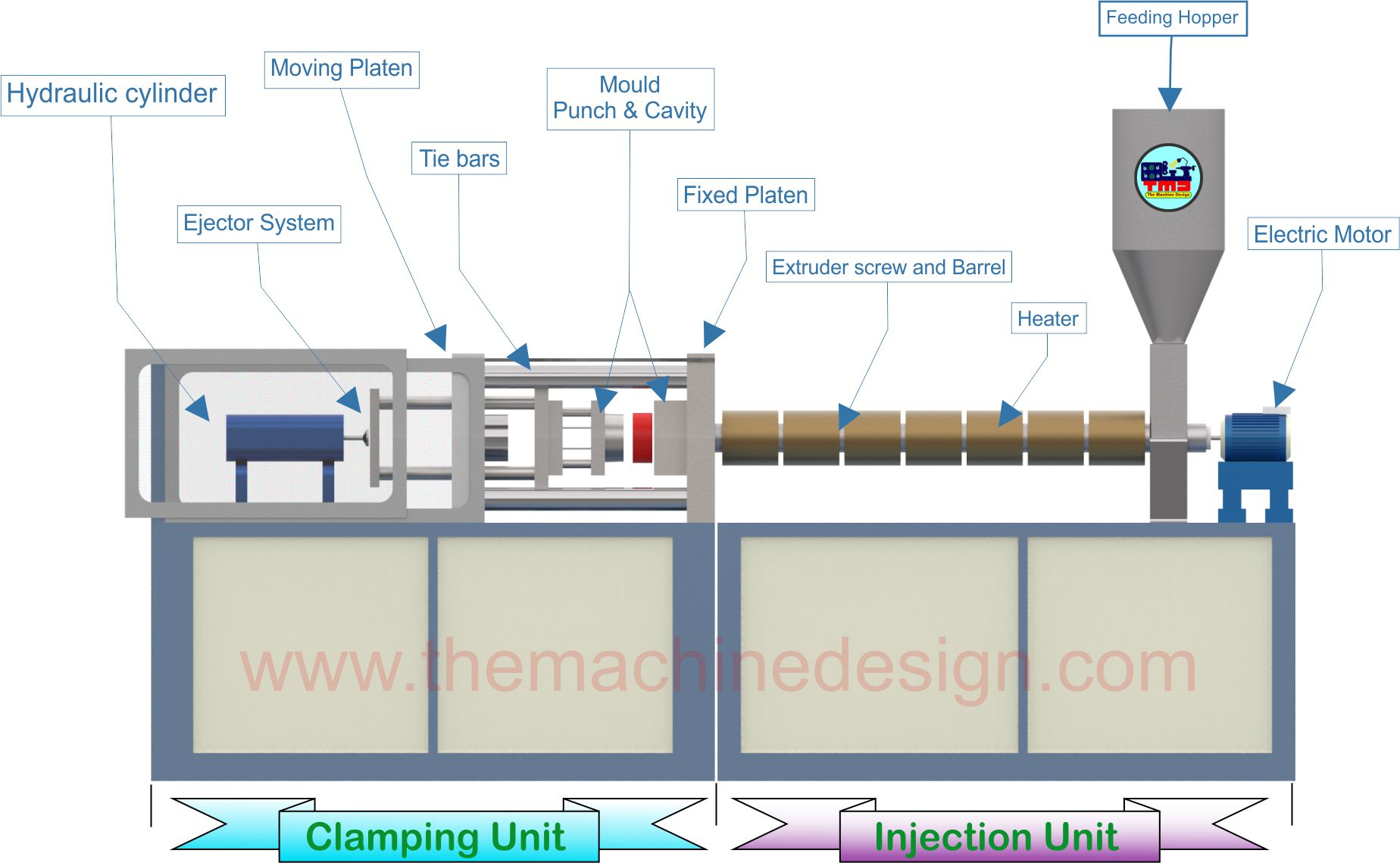

. The functions of the clamping unit are opening and closing a die and the ejection of products. With injection molding diversely shaped parts including those with complex shapes can be continuously and quickly manufactured in large volumes. Injection velocity plastic temperature plastic pressure and cooling temperature and time.

I have been successfully injection molding small the size of your small finger models of bones for my students to study anatomy and want to expand to injection molding a pelvis approximately 25 times the material size. Our Talented Diverse Skilled Experts Make Injection Molding More Economical Efficient. The tongs have 30-sec cycle time and are molded from ABS in a 462-g shot with the two parts weighing 23 and 211 g and the remaining resin making up the sprue and runner.

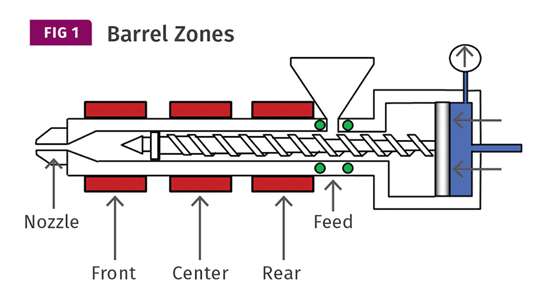

The molding-machine barrel must be chosen so that the plastic resides inside long enough for the plastic to melt but not so long as to degrade. The injection molding is a process to form the plastic resin into the desired shape. Injection molding machines come in different types such as.

It is an injection molding machine. Injection molding machine press the melted plastic into the mold and cool down by cooling system into solid designed shape almost all thermoplastics using this method comparing with other processing way injection molding has advantage of accuracy productivity it has higher. This column covers just the ninthswitchover response perhaps the most subtle and complicated yet one of the most critical of the nine.

The quality of a final molded part depends on the ability of a machine to deliver the optimum amount of plasticized material for the intended application. Reciprocating screw injection molding machines. Injection molding machines arent all that.

Clamping force as a function of surface area. The Beckhoff solution for injection molding machines is based on a universal hardware and software platform. Screw design In most cases a generalpurpose polyolefinic screw with a compression ratio of 21 to 251 and a length to diameter ratio.

While machine selection material properties and part design all affect the outcome of injection molding five processing variables specific to injection molding can have as much or more impact on the success of this process. Items that are too large for an injection moulding machines capability need to. Injection moulding is also not ideal for producing large parts as a single piece.

In the last two issues we started defining some basic tests to ensure your injection molding machine is working properly. There are several videos on YouTube of the mold-a-rama in action. The hardest part to source is the heating chamber as it is a piece of turned aluminum.

In a regular injection molding machine there. Ad Talk To Employee Owners For Your Custom Injection Molding Needs. I know Wikipedia says its a blow molding machine but Im afraid Wiki is also incorrect.

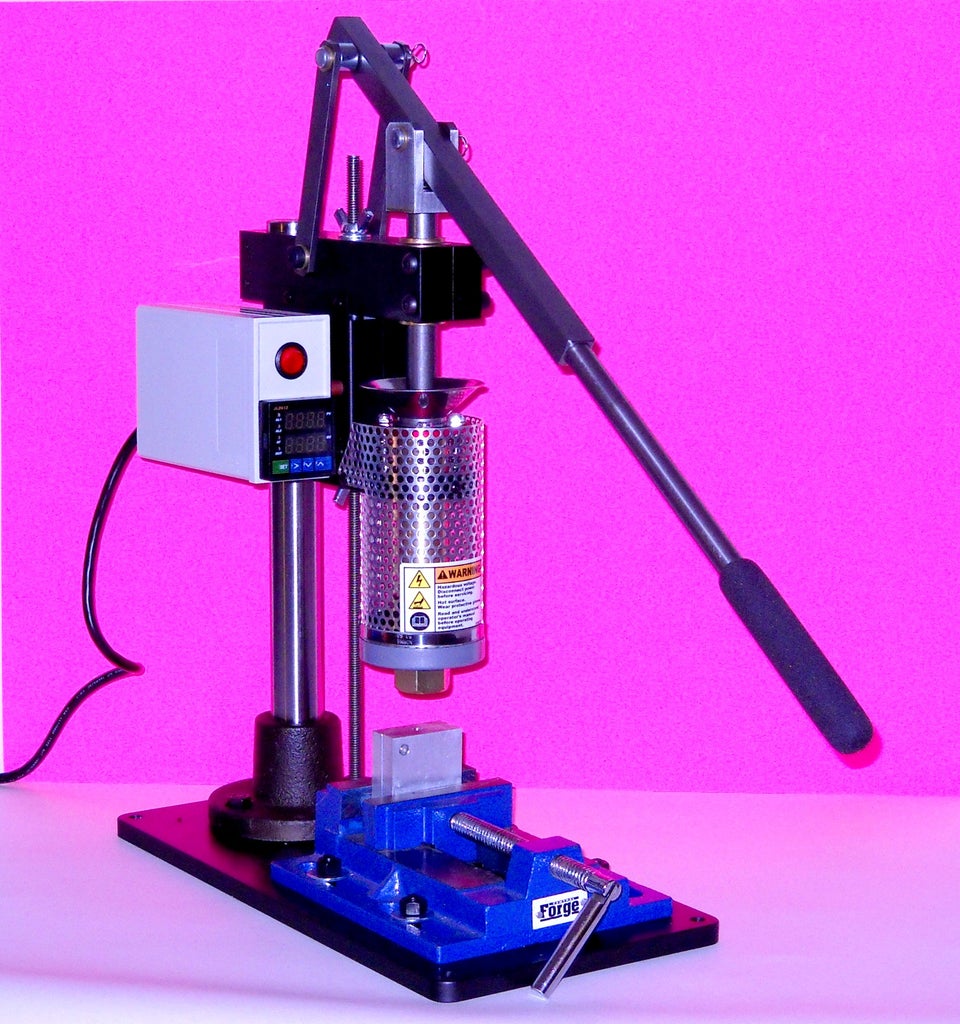

We Offer A Huge Products Selection Including Casters Glides Levers Tubing Hardware. Injection molding is awesome but for low volume runs making a simple rtv mold and using 2 part urethane pourable plastic is a lot more economical. Read on to see the best DIY and desktop injection molding machines.

A clamping unit and an injection unit. Ad Free Shipping Available. Wireless Data Fast Easy to Use.

17 thoughts on Tiny Homemade Injection Molder. Parts I and II covered the first eight of the nine suggested machine checks. There are 2 types of clamping methods namely the toggle type shown in the figure below and the straight-hydraulic type in which a mold is directly opened.

Injection molding machine is divided into 2 units ie. This is because of the size limitations of injection mould machines and the mould tools. Of course when Andy drops the fact that he made the buttons for the control panel on his homemade injection molding machine.

Injection Molding SIZING AN INJECTION MOLDING MACHINE Packing pressure 108Pa Clamping force F PA Figure 7. Therefore injection molding is used to manufacture commodities and products in a wide range of industries. Injection mold design needed for small part to be injection molded using a very rudimentary homemade desktop injection molding machine.

LNS Technologies Model 150A. It comprises an extensive portfolio of Industrial PCs EtherCAT as a fast communication system the decentralized IO modules drive technology components and TwinCAT automation software. The barrel and the screw play an important role in achieving this goal.

Ad Carpin Manufacturing Is The Industry Leader In Floor Protection Products. Injection Molding Machine.

Moldmaking Tutorial 2 Piece Scale Model Car Mold Youtube Injection Moulding Process Plastic Injection Molding Plastic Injection

Full Automatic Homemade Injection Molding Machine

Make Your Own Injection Molding Machine Make Diy Molding Diy Projects Homemade Machine

Tutorial Injection Molded Parts

Injection Molding Machine Construction Working And Applications

Diy All Electric Plastic Injection Molding Machine 3d Cad Model Library Grabcad

Injection Molding How To Set Barrel Zone Temps Plastics Technology

Homemade Injection Molding Machine Part 1 Youtube

Design And Fabrication Of Hand Injection Molding Machine Mechanical Project Youtube

How We Made A Tiny Injection Molding Machine Youtube

Diy Plastic Injection Molding Machine Test Youtube

Home Plastic Injection Molding With An Epoxy Mold 7 Steps With Pictures Instructables

Injection Molding Machine Part 2 The Extruder Screw Youtube Injections Machine Parts Molding

Injection Molding Molded Parts Plastic Injection Molding Process

Lns Technologies Plastic Injection Molding Machines And Supplies Photos Plastic Injection Moulding Machine Plastic Injection Molding Diy Molding

Buy Build A Plastic Injection Molding Attachment For A Drill Press Book Online At Low Prices In India Build A Plastic Injection Molding Attachment For A Drill Press Reviews Ratings

Injection Molding Terms And Definitions Tenere Inc

Make Your Own Injection Molding Machine Make Diy Molding Plastic Injection Molding Molding